Safety in the construction industry has notoriously been considered to be a “Field Issue”. Most design firms have taken an arm’s length approach and have considered the method of construction to be left to the contractor. Design professionals are cautious about being involved in the means and methods of construction fearing liability. Through conversations with other design groups, there is also a perception engineering has very little impact on job site safety.

At BlueScope Construction, we believe job site hazards can be reduced by the design, detailing, fabrication, and delivery of projects. A simple issue such as reducing double handling of a product on a job site reduces the chances of harm. A misplaced hole in a structural member whether it is caused by manufacturing or detailing can cause fieldwork and create an additional unnecessary hazard. Material shortage can cause the erector to work around the missing parts and require them to go back later and fill in.

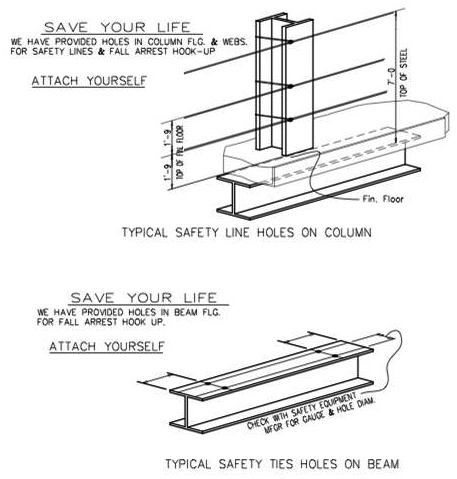

The following are examples of designing to reduce hazards.

All of us can have an impact on reducing job site hazards. We do want to include more design improvements in our Design for Safety Program. To achieve the most benefit for safety and financial results we feel a need to include the design for safety into our engineering software. We are open to new ideas for safety improvements so please send us your ideas.

In an attempt to increase our impact of “Design for Safety”, we contacted Dr. Michael Toole, an Associate Professor of Civil Engineering at Bucknell University. Dr Toole initiated and maintains the website Design for Construction Safety (DfCS) and Prevention thru Design (PtD). He has many interesting articles and presentations on the website which he would like to share with all of us in the construction industry. If you are interested please look at his websites: www.designforconstructionsafety.org and www.facstaff.bucknell.edu/ttoole

The following are quotes from one of his presentations which he shared with us and gave permission to use:

“Research conducted in the U.S., Europe, and other regions has shown that design does affect the inherent risk in the construction of a facility. Doctoral research by Professor Mike Behm at East Carolina State linked design to 22% of injuries that occurred in western states and 42% of fatalities across the country. European researchers found that nearly two-thirds of fatalities and injuries were linked to design. So we know that design does make a difference in construction safety.”

“Implementing Prevention Through Design (PtD) not only is expected to reduce construction site injuries, but also improve construction quality and increase worker productivity. Some revised designs also help improve safety during maintenance and operations of facilities. These derivative benefits provide additional initial and long-term incentive and value to the project owner, designer, and constructor.”